Some imagineering and CAD time brought about this design. The drivers are inside the cabinet, the fans and exhaust ports on the outside.

3D printing is basically AWSOME, I had these parts printed the next day on my printer. I even printed bolt on mounting slots for the PCB's

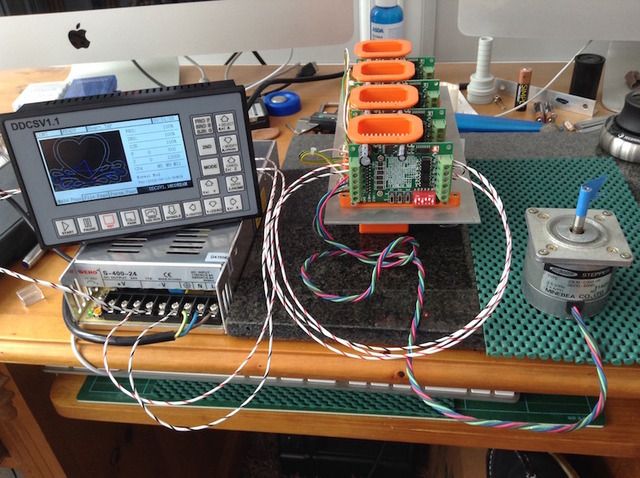

The initial design was going to use LinuxCNC for control, but I happened on some complete controllers that handle g-code for less than the price of Mach3. I will have to get it all up and running to be sure it will do everything I need. The g-code is transferred from PC to controller via a USB flash drive, so the only possible downside is no g-code tweaking at the console. For proven jobs this will be way faster and I no longer need a tower PC next to the router (full parallel port required for LinuxCNC)

All testing completed, I just need to route out a case now !!! Well, maybe once I have this lot jury rigged for that job. Thanks to Hobby Components for these great controllers, very underestimated for real CNC applications, next project will be a mill conversion.

Mac